Simple Design

You are visiting the Canada Kee Safety website from United States. Would you like to go to the United States site?

Tested and trusted. Kee Line has been rigorously tested on built roofs and endorse by 3rd-party safety validation.

Configured to Fit. Kee Line® uses has been engineered for multiple roof types and can be designed to accommodate varying building shapes.

Smart Personal Fall Protection. The Kee Line® horizontal life line system is a flexible, cost effective option for working at height.

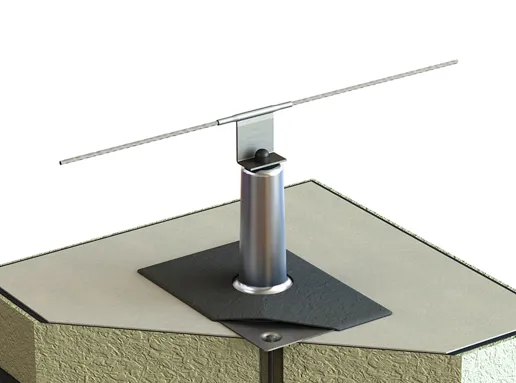

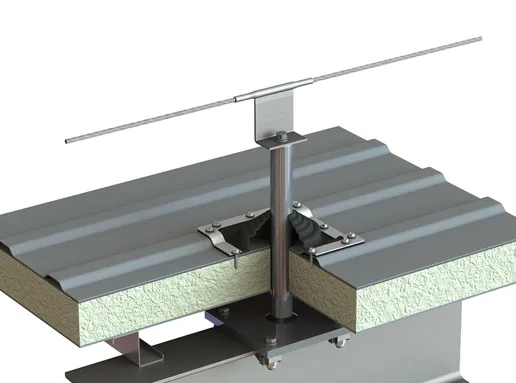

Kee Line® provides one of the only upright posts that can be weathered with a standard pipe detail.

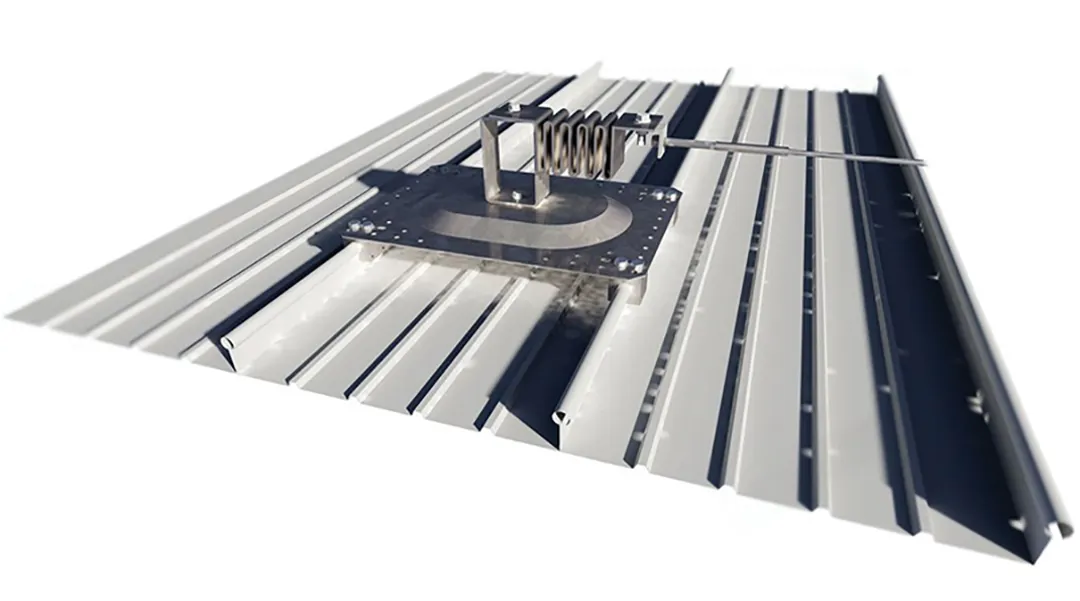

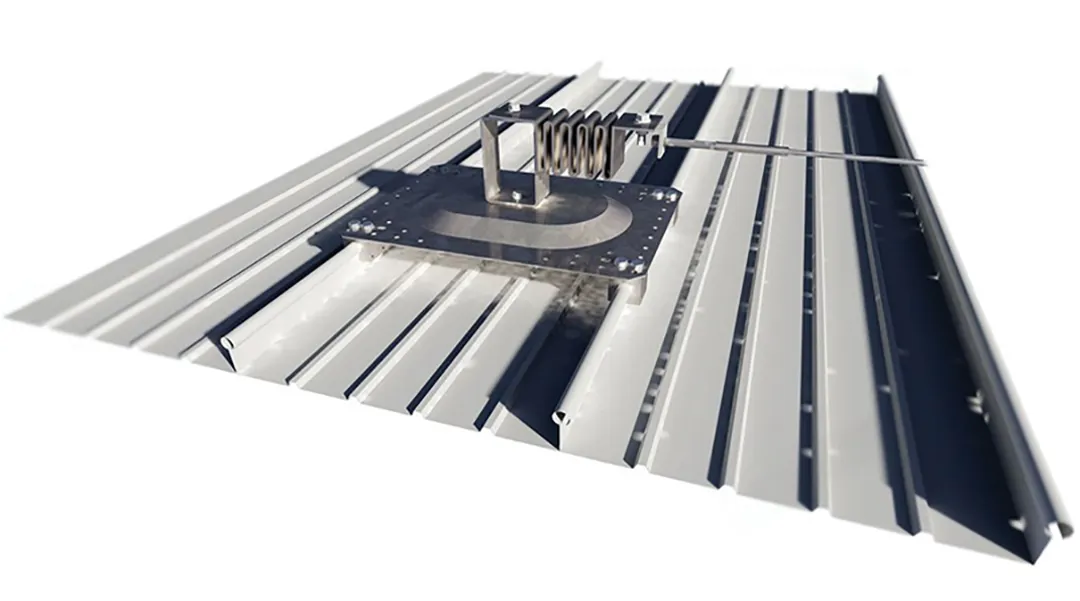

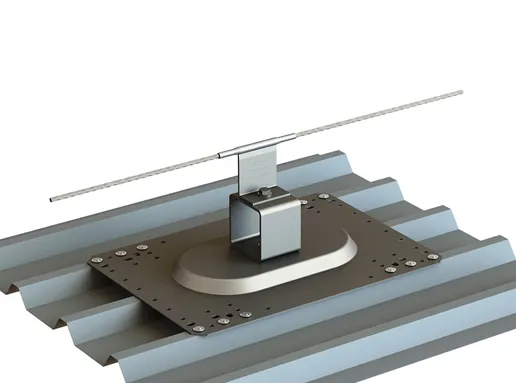

Utilizing the same range of brackets as standard roof systems, Kee Line® can be installed quickly and easily on standing seam roofs.

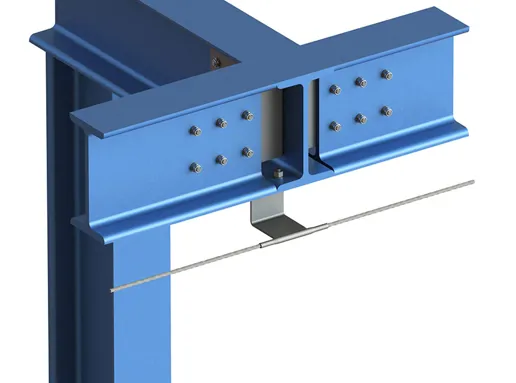

Kee Line® structural posts can be used to tie back directly to the frame of the building. These well-built, heavy-duty anchors can be welded to, wrapped around, or clamped onto underlying beam structures. They can also be mounted directly to concrete.

Provides personal protection for up to two users. Lifeline system is mounted directly above the user for tasks including overhead crane access, vehicle loading, machine & building maintenance, cleaning and access.

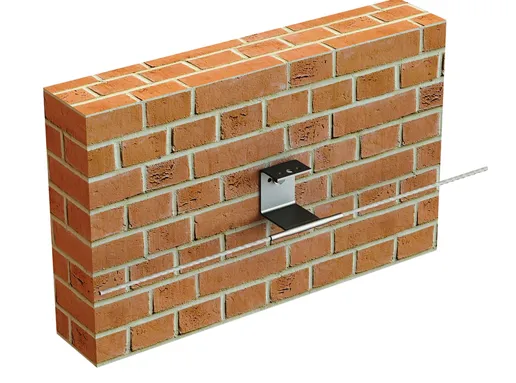

Kee Line® for Structures provides the horizontal lifeline components to allow mounting directly to concrete, steel, brick or stonework either in the horizontal or overhead application.

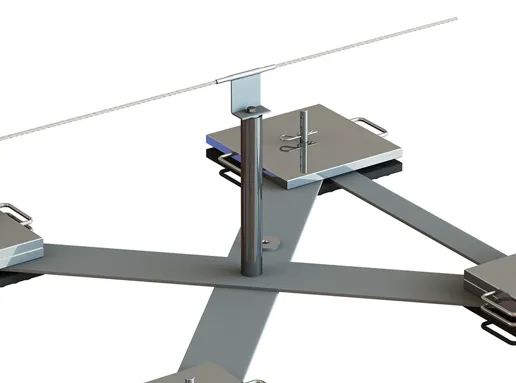

Kee Line® can create a permanent lifeline on a rooftop without the need to penetrate the roof structure. Each of the wire posts is connected to a weighted structure that keeps the user secure in the event of a fall.

Maximum span of 39′ allows 3 users at one time

A combination of galvanized and stainless steel components ensure longevity

We test internally and verify externally to maximize peace of mind

Kee Safety requires that Kee Line be installed by trained and certified installers

Kee Safety provides software validation to all Kee Line designs. Each design calculates building loads, vertical line stretch and other critical measurements to ensure that the system you receive will perform as expected and keep your team safe.

Kee Safety runs one of the world’s leading test and training centers at its UK headquarters. Run by a team of industry experts, this state-of-the-art facility ensures that Kee Safety products meet the needs of its customers. Kee Safety is committed to driving new innovation with the purpose of separating people from hazards.

We offer full design and installation services that include a complete on-site survey. Also, we can produce comprehensive shop drawings to help you visualize the end result. With our detailed project outline, you can be confident that your project is professionally specified, and that all safety concerns and standards are addressed to your satisfaction.

Alternatively, you can specify and install KeeGuard yourself with our easy-to-follow instructions – it all starts with a call to our knowledgeable staff!

Canadian National Standards (CSA)

Please complete the form below and we will be in touch shortly.